The metal casting marketplace is constantly evolving, pushed by the demand for greater precision, enhanced quality, and reduced defects. During this landscape, the pressure casting equipment performs a crucial position. nonetheless, for essentially the most demanding purposes, a specialised variety of casting machine is needed: the vacuum force casting device. this post explores the one of a kind benefits of these equipment, concentrating on how they boost the precision and high quality of steel casting, especially for cherished metals like gold and platinum.

Table of contents:

the benefits of making use of Vacuum tension Casting equipment for prime-excellent effects

How Vacuum tension Casting Enhances the Accuracy of Gold, Platinum, as well as other Metals

Why Vacuum strain Casting is Essential for High-Precision Industries

The Advantages of employing Vacuum stress Casting devices for prime-high-quality success

Vacuum pressure casting machines provide a significant breakthrough in comparison with conventional casting solutions. The Main benefit lies within the elimination of air pockets and gasoline porosity throughout the casting. By doing the casting approach beneath a vacuum, the molten steel is permitted to move a lot more freely and totally fill the mould cavity. This results in denser, stronger castings with less interior defects. Also, the applying of tension in the course of the solidification section helps to additional consolidate the steel, reducing shrinkage and improving upon the overall top quality. This can make vacuum tension casting ideal for manufacturing intricate and sophisticated models exactly where even the smallest imperfections can compromise the performance or aesthetic appeal of the final merchandise.

How Vacuum tension Casting boosts the Accuracy of Gold, Platinum, and also other Metals

The substantial value and one of a kind Houses of cherished metals like gold and platinum necessitate exceptional casting precision. Vacuum gold casting device technology is precisely created to meet these demanding demands. The vacuum environment don't just helps prevent oxidation in the molten metallic but in addition makes sure a clean up and reliable casting process. This is especially critical for gold, which can certainly tarnish or produce floor defects if exposed to air for the duration of casting. Additionally, the controlled pressure used during solidification encourages uniform grain structure and minimizes the chance of cracking or distortion. This results in castings which might be dimensionally accurate, possess excellent surface complete, and keep the specified mechanical Homes.

Why Vacuum force Casting is Essential for High-Precision Industries

higher-precision industries, like aerospace, health-related system production, and high-close jewellery output, trust in vacuum pressure casting to accomplish the stringent excellent requirements needed for their purposes. the chance pressure casting machine to deliver castings with restricted tolerances, small defects, and reliable content Attributes is paramount in these sectors. for instance, in the aerospace sector, vacuum force cast components are Utilized in critical motor pieces where by reliability and effectiveness are non-negotiable. likewise, in health-related machine manufacturing, vacuum tension casting makes certain the biocompatibility and structural integrity of implants. the advantages extend to jewellery building at the same time, where intricate models and flawless finishes are important for creating large-price parts. in the long run, vacuum stress casting delivers the required Regulate and precision to fulfill the demanding specifications of those industries. As evidenced by items similar to the TAKJ-VC-W out there at https://taeantech.com/products/takj-vc-w, these machines are especially created to cater towards the precision necessary by vacuum pressure casting procedures.

In summary, vacuum stress casting devices are indispensable instruments for reaching higher precision and remarkable quality in metallic casting. The mixture of vacuum environment and managed strain gets rid of prevalent casting defects, boosts materials Houses, and ensures dimensional precision. For industries demanding the highest amounts of effectiveness and trustworthiness, buying vacuum pressure casting technological innovation is not merely a choice but a requirement. Consider the distinct needs within your application and check out the varied vacuum stress casting alternatives accessible to unlock new possibilities in metal casting and elevate the caliber of your ultimate merchandise.

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Alisan Porter Then & Now!

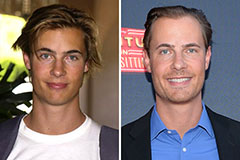

Alisan Porter Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!